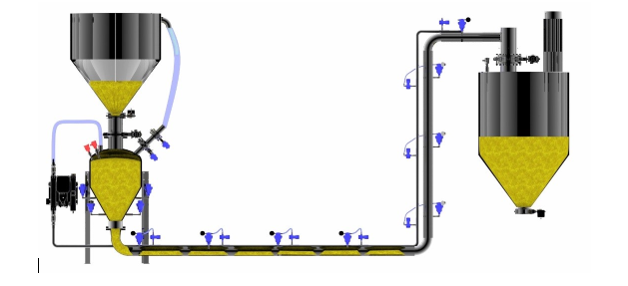

A lean phase conveyor is another type of pneumatic conveyor system used for transporting bulk materials, but it operates differently from dense phase conveyors. In a lean phase system, the material is conveyed in suspension within the air stream, typically at higher velocities and lower material concentrations compared to dense phase conveying. In lean phase conveying, the material is entrained within the air stream and moves in a relatively dilute phase, allowing for higher conveying speeds and greater distances. This method is suitable for materials that are free-flowing and non-abrasive, and it's often used for applications where high throughput and efficiency are key, such as in the handling of granular materials like grains, plastics, and certain chemicals. Lean phase conveyors offer advantages such as high throughput rates, versatility in conveying different materials, and the ability to convey over longer distances. However, they may not be suitable for fragile or sensitive materials, as they can be prone to degradation or damage due to the higher velocity of material movement within the air stream. Proper system design and equipment selection are essential to ensure optimal performance and minimize the risk of material degradation.

Parameters